In the extremely competitive pump industry, manufacturers are facing ever-increasing pressure to fine-tune business processes to improve profit margins.

Challenges facing pump manufacturers’ sales teams include application engineering support, high turnaround times, propensity for errors, etc. For a manufacturer to remain competitive, the sales cycle must be streamlined to improve efficiency and productivity of all its stakeholders.

Keeping up with changing business conditions is the key to success in this marketplace. Pump manufacturers must leverage technology to streamline traditional business processes in order to reduce costs, improve accuracy, improve customer and distributor satisfaction, and increase profit margins. Progressive-thinking companies that see change as an opportunity to differentiate themselves, have adopted configuration software technology to deliver better tools & support to their sales teams as well as business partners.

We have the answer to such challenges. For close to one & half decades, Configurator Solutions has been providing functionality-rich, end-to-end, custom-built software applications to the flow industry.

Whether your company's goals are to streamline the pump sales process or reduce brochure printing & distribution costs, software solutions from Configurator Solutions is the answer.

Our clients count on our software solutions for fast & accurate product configuration & pricing. Detailed datasheets, GA drawings & proposal documents can be quickly put together, providing customers with instant, detailed & thorough proposals. The software helps users select the most suitable pump, configure related accessories & components, perform price calculations & generate accurate & content-rich proposal packages.

As part of an overall sales solution, the software provides rich Business Intelligence / Analytics on your sales operations.

Analytics offer insights that improve your ability to understand and predict market shifts.

The software knows how to present data in a way you can use. It helps management collate &analyse crucial sales information into actionable business knowledge.

A digital dashboard enables users to make informed business decisions. Quickly drill down to identify trends, measure efficiencies, and work out strategies. Highlight every aspect of your sales funnel.

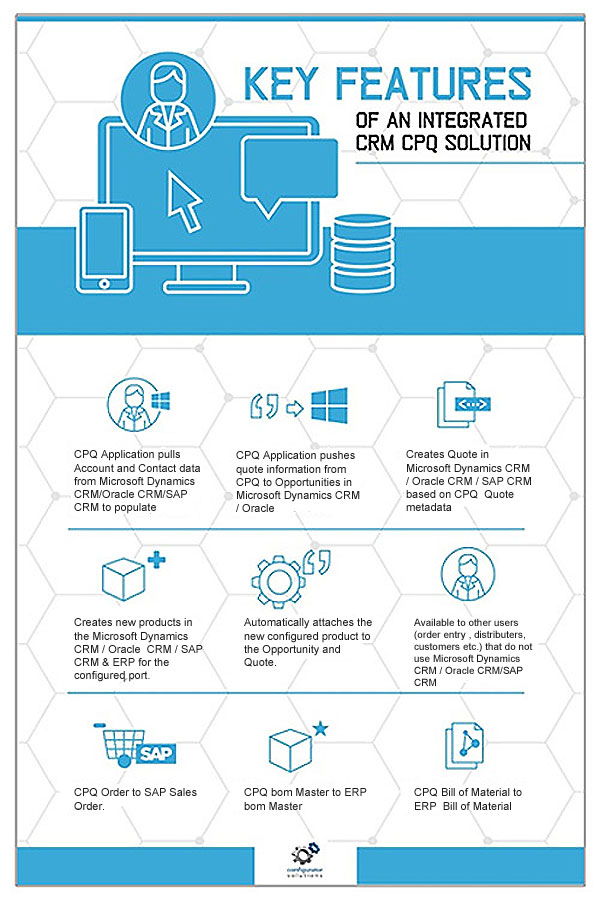

Since our solutions form part of a larger IT infrastructure, we routinely work with clients to integrate our solutions with their ERP systems / enterprise applications.

Integration of sales applications with enterprise systems helps multiply the advantage by protecting existing investments in technology, reducing manual intervention and enabling smooth flow of information across the enterprise. Post sales, ETO manufacturers need to be able to execute on final design and production. Their entire process from quote-to-order-to-production needs to be integrated so they can manufacture on schedule and within budget.

Our software is architected to be flexible and provide integration with boxed products as well as custom applications - CAD, MRP/ERP, CRM & other enterprise applications which enables it to assure rapid returns on investment (ROI).

Our engineered products data management tool & rules engine makes complex product & selection rule definition simple.

Our proven methodology coupled with experienced domain experts & project managers helps document your products’ application engineering rules to create a strong foundation of a well-structured knowledge base.

Product data & rules are detached from the configurator and maintained separately with controlled publishing. The rule-building process is GUI-driven, and no programming skill is required. Rules are build in an intuitive manner. Product information is defined in a scalable and easily-maintainable manner. Its easy to add new products, brands, models…

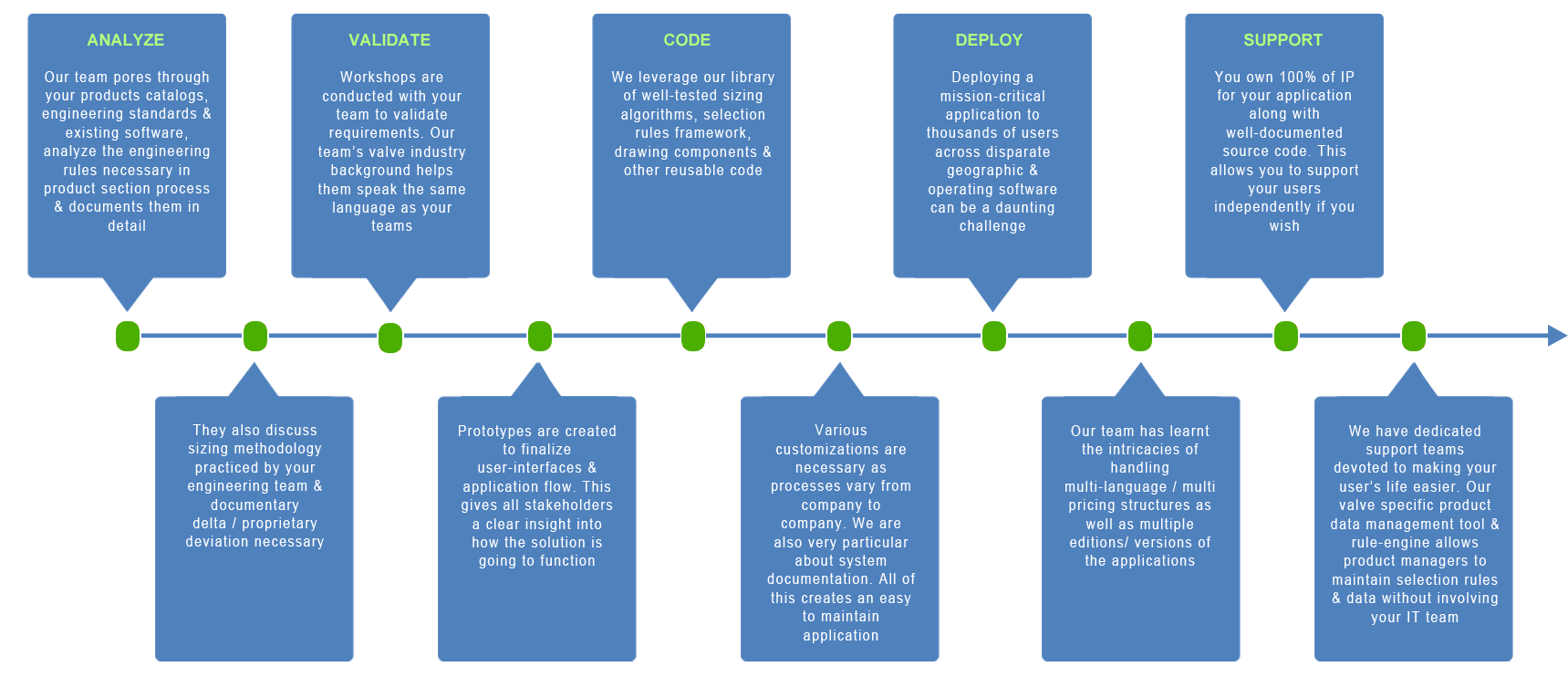

precisePump has been developed with the objective of providing an effective guided sales solution for engineered products companies. And Configurator Solutions is committed to ensuring quick returns for you on this strategic investment. Which is why implementation, training & support form an integral part of our solution.The implementation process is multi-stage. Our consulting team works with senior executives from your organization to develop an implementation blueprint. We carry out an extensive study of your product lines and their features, the selection & configuration rules as well as your sales process. We also keep in mind the key objectives behind your decision to implement precisePump. A proactive support mechanism ensures that the benefits sustain over time. Support is an ongoing process during which we address any problems that might be faced by users. For example, application defects / usage issues, defect fixing, change requests, support for new product lines, changes to product selection rules, difficulties faced during installation or issues with project files.

Today's pump marketplace is highly competitive, with manufacturers facing intense pressure to streamline & improve business processes. Technology-driven manufacturers are hence adopting software applications to optimize their product sizing, selection & quotation processes, to increase accuracy & productivity of their sales teams.

precisePump is a guided sales software for the pump sizing, selection & quotation or pump CPQ process. Its intended users are sales teams, application engineers, representatives or distributors, and end-customers. It helps automate & streamline the sales cycle and helps your organization and business partners make better decisions. It is not a CRM application, but software that enables pump sales teams to quote easily, quickly & precisely.

It is custom-developed to fit your business needs and sales process. The solution has been architected for the Windows, Web & mobile platforms. Ease of use, scalability, a consistent look & feel across platforms & integration with enterprise applications are its technology highpoints.

Various calculations are performed by the software during the pump selection & configuration process. These include:

Users can calculate the total head for the system at the required flow rate. The software inputs the suction and discharge piping parameters including tank conditions, pipe length, pipe material and sizes valves & fittings. Using the desired flow rate, it calculates the total head for the system.

Complete selection & configuration of pump system is performed according to specified operating conditions. Pump selection is based on parameters such as:

Comparing alternative configurations enables the user to evaluate multiple options in order to arrive at the most suitable configuration as per priority of performance or cost. Ranking of suitable options is done based on efficiency, speed, Best Efficiency Point, BKW, minimum capacity, impeller diameter & price.

Pump configuration is carried out in several steps. The software checks if the selected pump meets all the required parameters. All available configuration options are displayed during selection.

Each component of a pumping system such as hydraulics, shaft seal, prime mover, coupling or base frame are selected by combination of technical attributes.

Choose the best fit for purpose valve from a set of valid configurations, against key performance parameters

Selection of accessories is done either as per a selected configuration or via name or item number. It is possible to define parts necessary for the dimensioning of the pump or additional elements like colour or warranty extensions as an accessory. Accessories can be classified in the database program or combined to groups. Accessory classification is done according to selection steps (e.g. mechanical or electronic accessory).

Search & selection of spare parts, which can be used independently of the product or depending on the selected pump aggregate, is possible. Selection of the respective spare parts is done via the spare parts list / drawing. Definition of different prices for different markets is also possible.

Pump pricing is performed according to the selected configuration including all components and accessories, as total price or on the basis of single components. Product configuration is linked to the price table and if necessary item number. Integration with other applications, such as ERP systems, is possible.

Your pricing policy is enforced to ensure consistent & competitive quotes. A recommended spares list can also be generated for commissioning & operations. Management of prices for different markets and support for different currencies are also offered.

A comprehensive, content-rich proposal package can be generated aligned with the organization's business needs. The contents include:Covering Letter

Performance curves such as viscous performance curve, consistency performance curve, VFD (Variable frequency drive) curve, VFD + viscous performance curve, etc. available as per user selection along with duty points.

Our guided sales configurator software (CPQ software) for pump sizing, selection & quotation simplifies & speeds up your sales process. It leads your sales teams to optimal pump configurations based on customer requirements.

The process of performing engineering calculations, evaluating suitable product alternatives & finally generating the necessary commercial documentation is fully automated. This reduces errors & boosts sales productivity. Risk of missed opportunities caused due to insufficient time to respond is reduced. Accuracy of quotes is enhanced. Knowledge about product configuration is captured in the form of rules assisting the retention of crucial product & process knowledge, mitigating the risk of knowledge drain.

We enable you to deliver product & pricing knowledge directly to your sales force, ensuring that you meet your customers' needs for complex engineer-to-order products. Application engineering knowledge is captured in the form of engineering calculations and selection & configuration rules. And the application engineering team is able to focus on more critical cases / complex configurations.

Office 212, Shoppers Orbit, Vishrantwadi,Alandi Road, Pune 411015, India

+91 (20) 4075-7642 / 612

Solutions@ConfiguratorSolutions.com

Sales@ConfiguratorSolutions.com

Configurator Solutions

Configurator Solutions develops sales configuration software for manufacturers of engineered-to-order (ETO) products & equipment such as control valves, safety vales, pumps, gauges, etc.